Partnerships

Collaboration across the supply chain

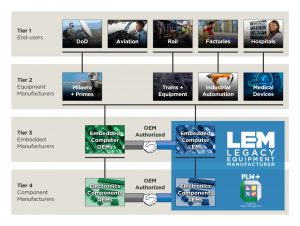

Mature products are time tested, but time isn’t kind to products. Assuring longevity is so much more than simply sourcing obsolete components. Program managers and product engineers responsible for sustaining long-life applications must establish partnerships across the entire supply chain to be fully effective.

GDCA sees legacy and sustainment as a process that involves the entire embedded supply chain, from component suppliers and test labs to embedded board OEMs and application OEMs.

We utilize our collaborative partnerships with all supply-chain players to provide end-to-end solutions and to help achieve application longevity.

Specialists

These are the champions of a program’s critical technology. They provide the knowledge necessary for sustaining, supporting, and managing the products businesses rely on. Their expertise is critical in supporting sustainment dominated systems.

When it comes to our partners, they’re some of the best in the industry at what they do. This includes the engineering teams hired to both design new products and sustain mature products.

When it comes to our partners, they’re some of the best in the industry at what they do. This includes the engineering teams hired to both design new products and sustain mature products.

As part of collaboration, we recognize that not everyone holds all the answers. While we bring our experience sustaining mature and legacy technology to the table, it’s our partnership with all the engineering teams and specialists that gives us insight into both the challenges experienced and the solutions required to keep systems going.

At the heart of sustaining a quality product are the specialists who understand the system inside and out. Through these partnerships, together with a proactive obsolescence management and sustainment plan, we overcome the challenges faced by legacy products.

Suppliers & Original Component Manufacturers (OCMs)

Components are the building blocks of embedded systems. Thus, the shift from Obsolescence Management to LifeCycle Sustainment on embedded computer boards starts with components.

Making the shift from EOL to legacy needs to start here. Take any long-lasting electronic system, and the basic building blocks begin with quality components. Moore’s Law directly speaks to how innovation changes the very shape of what goes on a modern embedded board.

Making the shift from EOL to legacy needs to start here. Take any long-lasting electronic system, and the basic building blocks begin with quality components. Moore’s Law directly speaks to how innovation changes the very shape of what goes on a modern embedded board.

But what we’ve seen at GDCA centers on the very fact that no part of the supply chain is isolated. These issues go beyond pieces and parts and concern the entire embedded system. NDAA, legislation, and the clamoring need for OEMs and end users across the supply chain are raising the stakes for OCMs. From brand to customer loyalty, OCMs are feeling the pressure to respond. Haphazard slices off underperforming product lines damage customer trust and cripple industries with long-lasting systems.

This is why GDCA has focused on forming collaborative partnerships with OCMs focused on ensuring that information regarding component life cycles and availability is transparent and accessible.

Application OEMs

Innovation and design come together to create cutting-edge technology the world needs to thrive. However, sometimes “cutting-edge” is not yet necessary or feasible, and it is more important for “old’ technology and systems to remain long lasting. Application OEMs often find themselves in a situation in which they can’t or aren’t ready to upgrade, yet have to, due to component obsolescence issues. Proactive Legacy Management (PLM+™) allows application OEMs to get a “second life” for so-called “obsolete” critical systems.

Application OEMs bring quality products and designs together to provide innovative solutions or to solve specific problems. These OEMs spend countless years and resources developing a product or system to meet their customers’ needs. By the time they make it through design, these applications are critical systems, often having life-spans well past the five- seven-year life cycle of the components and boards they require to exist.

Application OEMs bring quality products and designs together to provide innovative solutions or to solve specific problems. These OEMs spend countless years and resources developing a product or system to meet their customers’ needs. By the time they make it through design, these applications are critical systems, often having life-spans well past the five- seven-year life cycle of the components and boards they require to exist.

All too often, application OEMs find themselves at risk of obsolescence, especially if they invest using a product already well into its life cycle. In fact, it isn’t unusual for some industries to even

have several waves of obsolete components hit before a product even makes it into production.

This is why these OEMs find it so helpful to partner with us. Working with us early in the application life cycle ensures not just the production schedules they’ve committed to but ongoing access to critical IP and products.

Distributors

Distributors can serve as a liaison for customers to access a broad spectrum of embedded computing technology. Distributors are often able to provide a channel for customers to find long-term product support and a wide variety of obsolescence management solutions.

As OEMs bring products to the market, distributors act as an additional channel for customers. For customers integrating technology, a distributor can be a channel for finding the right off-the-shelf product to go into a larger custom system as well as offer ongoing support for engineering challenges. Distributors are often the channel that EOL, product change notices (PCNs) and engineering change notices (ECNs) get sent through because they often maintain an active customer base.

As OEMs bring products to the market, distributors act as an additional channel for customers. For customers integrating technology, a distributor can be a channel for finding the right off-the-shelf product to go into a larger custom system as well as offer ongoing support for engineering challenges. Distributors are often the channel that EOL, product change notices (PCNs) and engineering change notices (ECNs) get sent through because they often maintain an active customer base.

Through partnerships with our distributors, GDCA has been able to proactively sustain customers who find themselves facing End-of-Life, where:

- LTB needs were underestimated

- Applications are having a “second” life

- Follow-on international sales caught them off guard

- Redesign and recertification is too expensive

Organizations and Thought Leaders

“All progress is precarious, and the solution of one problem brings us face to face with another problem,” said Martin Luther King Jr. Solutions brought forth by innovative technologies eventually bring to light obsolescence problems and risks. These challenges can be managed by collaborating with individuals and partner organizations across the supply chain.

Counterfeits,  obsolescence, non-conforming material, DMSMS, production downtime, recertification, and redesign are some of the risks that come in the wake of technology and innovation. Moore’s law remains a constant companion as technology gets smaller, more complicated, and more difficult to sustain.

obsolescence, non-conforming material, DMSMS, production downtime, recertification, and redesign are some of the risks that come in the wake of technology and innovation. Moore’s law remains a constant companion as technology gets smaller, more complicated, and more difficult to sustain.

An individual can be a powerful voice for change, but it is the dialogue and collaboration between key organizations and individuals that uncovers new solutions. Those who devote valuable time and energy toward solving these challenges provide the embedded industry with best practices and provide warnings for the risks coming down the road.

While most think of innovation as something only applied to the design and development of new technology, at GDCA, we see partnership, innovation, and creativity as critical elements of turning the hardships of “obsolescence mitigation and management” into an easily navigated business process.

Partnerships with thought leaders, organizations, and the whole supply chain provide a way to support embedded technology — sustaining ongoing legacy instead of forcing obsolescence.